STAQ Pharma Outsourcing Facility

CLIENT | OWNER:

STAQ Pharma

PROJECT LOCATION:

Denver, CO

KEY WORDS:

Biosafety Cabinets, Cleanroom, DX Cooling, Energy Efficient, Feasibility Study, ISO-5 Class, ISO-7 Class, Prefabrication

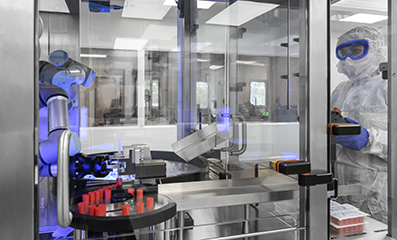

STAQ Pharma is transforming pediatric healthcare by addressing a critical gap in the pharmaceutical supply chain: the availability of sterile, small-dose medications for children. At its cutting-edge 18,400-square-foot cGMP 503B outsourcing facility in Colorado, this innovative startup repackages adult-dose medications into precise pediatric doses using advanced robotic automation. These smaller doses are essential for pre-operative, operative, and post-operative procedures in pediatric care.

The facility includes 5,000 square feet of highly automated cleanroom space designed to meet the highest standards for sterile-to-sterile drug repackaging. Robotic systems ensure exceptional sterility, accuracy, and efficiency, helping STAQ Pharma deliver safer and more reliable medications for pediatric patients.

To support this pharmaceutical-grade environment, the HVAC system maintains an ISO 7 cleanroom classification through a cascading clean-to-dirty pressure hierarchy. Inside the robotics enclosure, conditions are even more stringent, achieving ISO 5 classification. Energy-efficient design strategies, including variable airflow modes for occupied and idle states, enable significant energy savings while maintaining strict air-change requirements.