Clean/Non-Destructive Test Lab

CLIENT | OWNER:

BAE Systems

PROJECT LOCATION:

Boulder, CO

KEY WORDS:

Aerospace, As-Builting, Award Winning, BIM, Chemical Handling, Cleanroom, Construction Administration, Dust Collection, Electrostatic Discharge Protection, Power Distribution, Research Facility

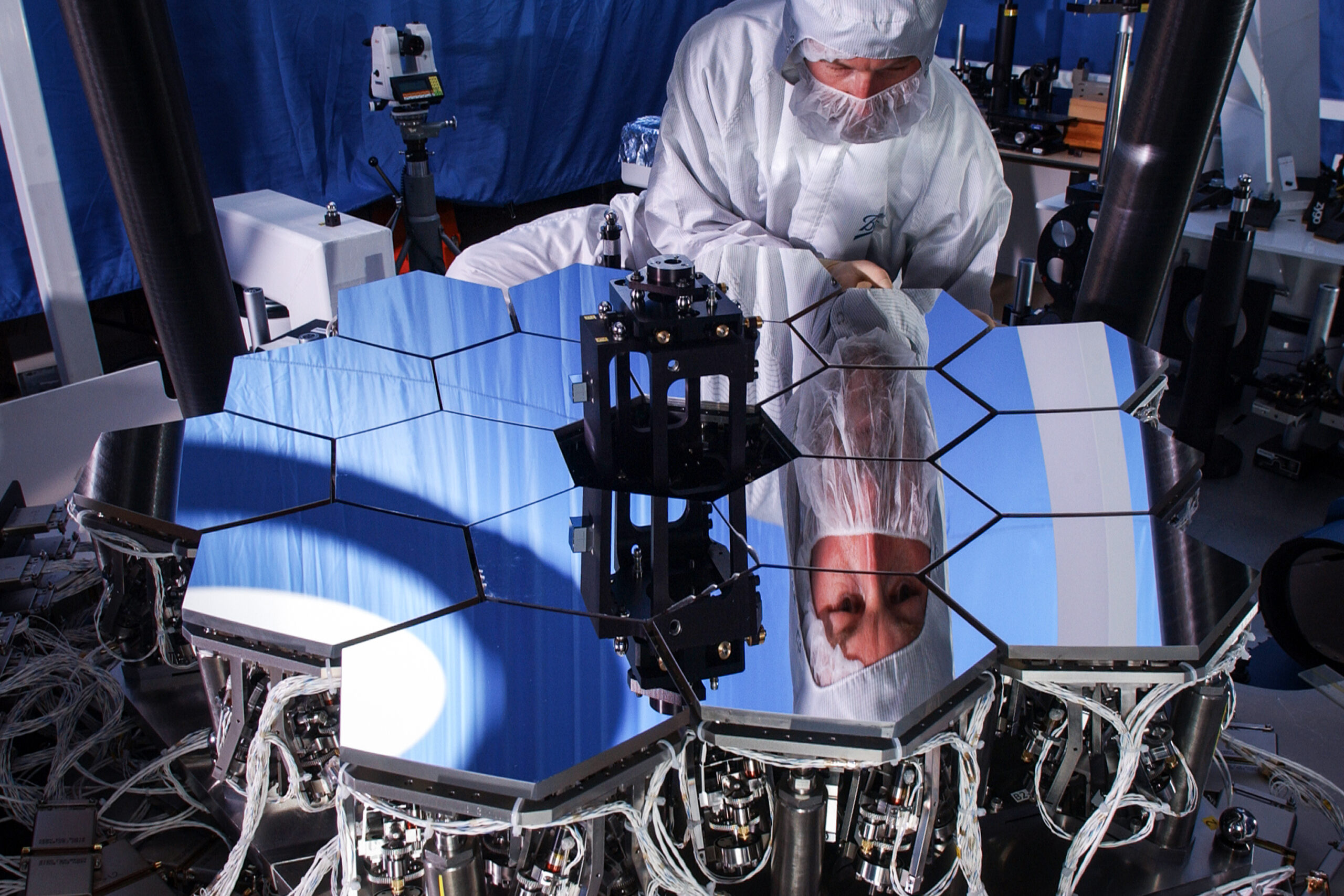

BAE System’s specialized testing and manufacturing facilities support critical space missions, including the James Webb Space Telescope (JWST) program. The 4,042-square-foot clean/non-destructive test lab was developed to thoroughly clean and test critical flight hardware for national asset programs. As the next-generation Hubble Telescope, the infrared JWST enables astronomers to study the entire history of the universe. The lab’s built-in flexibility accommodates testing and cleaning for other satellite missions as well.

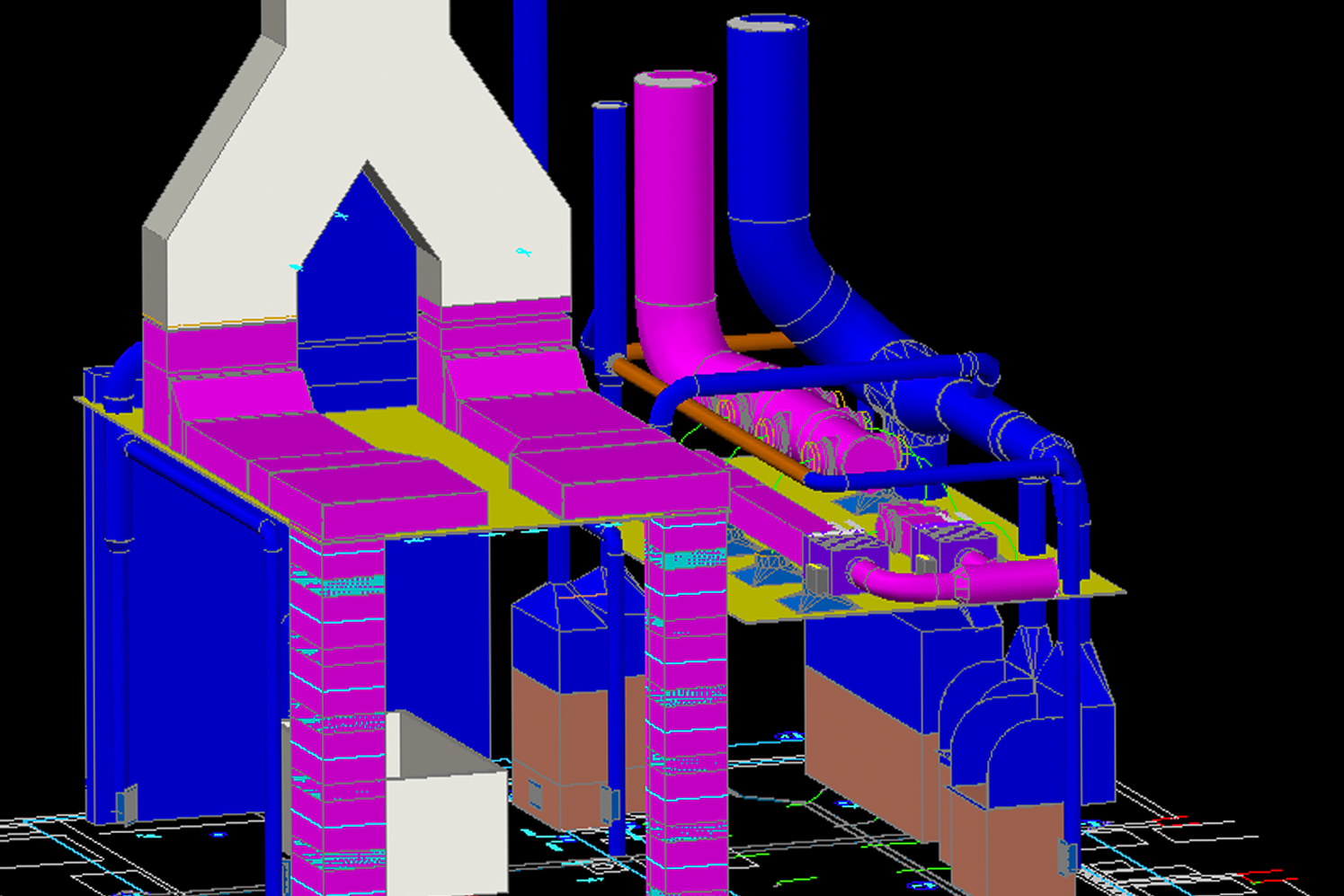

The lab’s large parts spray room, where bulkier flight hardware is cleaned with hazardous solvents, features an innovative air-diffusion system that delivers evenly distributed, cleanroom-quality airflow. This system moves vapors away from staff and limits flammability risks. Building Information Modeling (BIM) software was used to design large, complex ductwork for the small ceiling plenums in the spray rooms. Additional safety measures include applying intrinsically safe process piping controls to limit voltages in the presence of flammable vapors and developing a chemical container emergency depressurization system.

As the project’s mechanical and electrical engineer, RMH designed custom air systems to address the limited plenum space. The design incorporated vertical unidirectional airflow using fan-filter units, a custom hood, hazardous exhaust systems, and point-of-use laboratory systems, including nitrogen, house vacuum, deionized water, and dust collection. Electrical systems included electrostatic discharge protection, heavy power for support equipment, photosensitive “yellow” lighting, branch grounding, and overhead hoist electrical systems.